How to choose the right packaging machine?

With the development of logistics business and the popularity of e-commerce, the demand for packaging has increased significantly. And automatic packaging machine equipment came into being. It not only improves the efficiency of packaging for businesses, but also ensures the quality of packaging.

what is the automatic packaging machine equipment?

Automatic packaging machine equipment is a kind of CNC packaging equipment. It can not only measure, seal and seal the packaging, but also output the finished product to the production line. Compared with other packaging equipment, it has obvious advantages, because the automatic packaging machine equipment is simple, fast and stable, which can greatly improve production efficiency and reduce costs.

When using a fully automatic packaging machine, it can realize automatic packing, heat shrink film, heat shrink, automatic packaging and other functions. In the packaging process, it can be automatically adjusted according to the set requirements, such as size, specifications, materials, etc. Each step is done automatically, without manual action. And the use of it can also greatly improve the packaging speed, so that production efficiency reaches the highest point.

There is no denying that purchasing packaging machinery can be a big investment for your business. But if you’ve done all the necessary research, it could be worth the investment. Not only is it cost effective and filtration free, but it also makes packaging much faster.

Utomatic packaging machine advantages:

(1). High efficiency: The automatic packaging machine can quickly and accurately complete the packaging work, significantly improving production efficiency.

(2)Automation: The automatic packaging machine realizes the automation of the packaging process, reduces manual operation and reduces labor costs.

(3)Flexibility: The automatic packaging machine can be customized according to different product characteristics and packaging requirements to adapt to different production needs.

(4)Reliability: The automatic packaging machine has high reliability and can ensure long-term stable operation.

(5)Environmental protection and energy saving: Automatic packaging machine can effectively reduce energy consumption and waste generation, in line with modern environmental protection concepts.

How do we choose the right packaging machine?

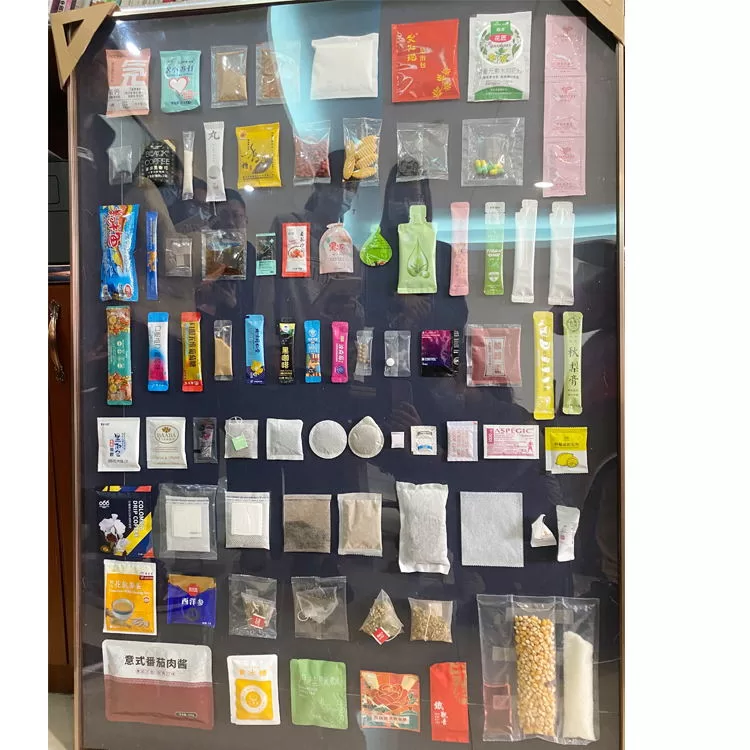

1.Packing machine types

(1)Automatic liquid paste packaging machine : shampoo, soy sauce bag, vinegar bag, grease, grease, cosmetics and other liquid paste.

(2)Automatic particle packaging machine is suitable for: sugar, coffee, fruit, tea, MSG, salt, desiccant, seeds and other particles.

(3)Automatic powder packaging machine : milk powder, protein powder, starch, coffee beans, seasoning, powder, pesticide powder and other powder powder.

2.Product types

(1)Pillow bag

(2)stand-up bag

(3)Paper bag

(4)Triangle bag

(5)vacuum bag

3.Packaging machine appearance

Beautiful design, generous and effective, in line with the design specifications of vacuum pump packaging machine. In addition, the edge of a good packaging machine is smooth and smooth.

4.Packaging machine raw materials

Automatic packaging machine steel frame structure must have a certain thickness, and can be. In addition, there are also differences between spraying and stainless steel plates. Stainless steel plate automatic packaging machine is stronger than paint packaging machine.

5. Packaging machine parts:

Select parts with good characteristics of automatic packaging machine, parts use period is poor, wide comfort is low.

6.Packaging machine brand:

In addition to providing customers with qualified products, reliable manufacturers can more easily carry out product maintenance and after-sales repair services. Therefore, to some extent, the products of good manufacturers are stronger.

Four major operation steps of the packaging machine and its precautions:

1. Place the packaging machine materials:

First of all, we need to prepare the materials of the packaging machine, such as your product, your packaging container, the material of the product, etc., and put them in the corresponding position for the normal use of the packaging machine.

Precautions: It should be noted here that before using the packaging machine, it is necessary to ensure the cleanliness of the packaging machine, especially the packaging machine with filling technology, which is easy to hide dirt and cause secondary pollution of the product. In addition, the packaging container should be suitable for the size of the packaging machine.

2.Open the power switch of the packaging machine:

After the materials and containers used in the packaging machine are ready, the power switch of the packaging machine is opened and the packaging machine is officially started. Precautions: It should be noted here that before opening the power switch of the packaging machine, it is necessary to check its power line, if the power line has exposed places, it is necessary to replace the power line in time, otherwise it is easy to cause the risk of leakage, and it is also easy to damage the packaging machine equipment.

3.Packaging machine parameter setting:

After the packaging machine is switched on, the touch screen of the packaging machine will also start, we must click to enter the parameter setting of the packaging machine, according to the packaging machine instructions for temperature, sealing time, sealing speed, filling capacity value and other parameters to ensure the normal use of the packaging machine. Precautions: It should be noted here that the parameters of the packaging machine must be set according to the instructions of the packaging machine, such as the sealing temperature of the packaging machine is 200 degrees, if the set temperature is lower than 200 degrees or higher than 200 degrees, there will be bubbles in the sealing, or the sealing film is not correct.

4. Packaging machine start :

After everything is ready, the packaging machine can be officially started, directly press the “start” on the main menu, the packaging machine can operate normally!

Note: In the process of starting the packaging machine, we should observe the temperature of the machine at any time, if the temperature is too hot, we should stop the operation and wait for the packaging machine to cool for half an hour before the operation, so as to avoid excessive temperature resulting in the failure of the packaging machine equipment. In addition, if the packaging machine is abnormal during operation, the packaging machine should be turned off immediately, and then started after inspection and maintenance.

In short, automatic packaging machine equipment has become an indispensable industry chain link in the packaging industry. Using it can enable manufacturers to improve packaging efficiency and reduce brand costs. The development of automatic packaging machine equipment has brought major changes to the packaging equipment industry, and also provides high-quality and efficient packaging services for enterprises, which is one of the indispensable advanced equipment for businesses.

-

Finding the Right Auger Filling Solution: Semi-Auto vs. Automatic Machines

04-05-2025 -

Precision Meets Efficiency: How Auger Filling Machines Revolutionize Powder Packaging

04-05-2025 -

The Future of Packaging: How Automatic Machines Are Revolutionizing the Industry

04-05-2025 -

Overview of Packaging Machine Buying Guides

08-01-2024 -

How Does a Vertical Form Fill Seal Machine Work?

30-10-2023 -

Advancements in Auger Powder Filling Technology

27-10-2023 -

A Deep Dive into Automatic Packaging Machines

26-10-2023 -

The Revolutionary Fully Automatic Potato Chips Packaging Machine

20-09-2023 -

How to choose the right packaging machine?

23-08-2023 -

Reducing Waste And Maximizing Yield With Multihead Weigher Machines

15-03-2023